Kevin Burns 9306 2.0 putter review – Club Junkie Reviews (Golf WRX)

Technology

Pyramid Groove Face Milling

Our signature pyramid grooves have been meticulously crafted to offer a softer, more responsive feel with every stroke. Designed for superior performance, these grooves initiate immediate ball roll and reduce energy transfer to the ball, resulting in unparalleled speed control and accuracy.

Supported by scientific data from the Quintic machine, Kevin Burns Putters boast the smallest impact ratio on the market. This results in a truer roll and superior speed control.

Customize

Two piece Interchangeable Hosel

Our innovative interchangeable hosel construction, enables effortless customization of lie angles, lofted heads, and neck styles.

Our advanced two-piece putter design eliminates the need for bending, as the lie angle is precision-machined directly into the neck of the putter. KB Golf is the sole company in the market to offer this cutting-edge feature

Performance

Tungsten Weighting

In 1996, Kevin Burns Golf made history as the pioneer in utilizing tungsten weighting in a putter. Today, Kevin Burns Putters proudly feature a dual tungsten weighting system. Specifically engineered, the "toe" weight is slightly larger than the "heel" weight to accommodate for the weight of the neck. This design ensures the sweet spot of the putter is precisely centered, a feature we refer to as "center balanced."

Two-Piece Interchangeable Hosel

Our innovative interchangeable hosel construction, enables effortless customization of lie angles, lofted heads, and neck styles.

Our advanced two-piece putter design eliminates the need for bending, as the lie angle is precision-machined directly into the face of the putter. KB Golf is the sole company in the market to offer this cutting-edge feature

303 Stainless Steel

Each Kevin Burns putter is meticulously crafted from a solid block of 303 stainless steel, embodying our commitment to producing the finest milled-to-specification putters.

Every Putter Has A Story

Kevin Burns Putters stands as the sole provider in the market offering milled-to-specification lie angles and lofts, alongside a diverse selection of four distinct neck styles featuring various offsets. Additionally, we offer six unique line configurations and three interchangeable weighting options, ensuring unparalleled customization for discerning golfers.

Center Balanced

In 1996, Kevin Burns Golf made history as the pioneer in utilizing tungsten weighting in a putter. Today, Kevin Burns Putters proudly feature a dual tungsten weighting system. Specifically engineered, the "toe" weight is slightly larger than the "heel" weight to accommodate for the weight of the neck. This design ensures the sweet spot of the putter is precisely centered, a feature we refer to as "center balanced."

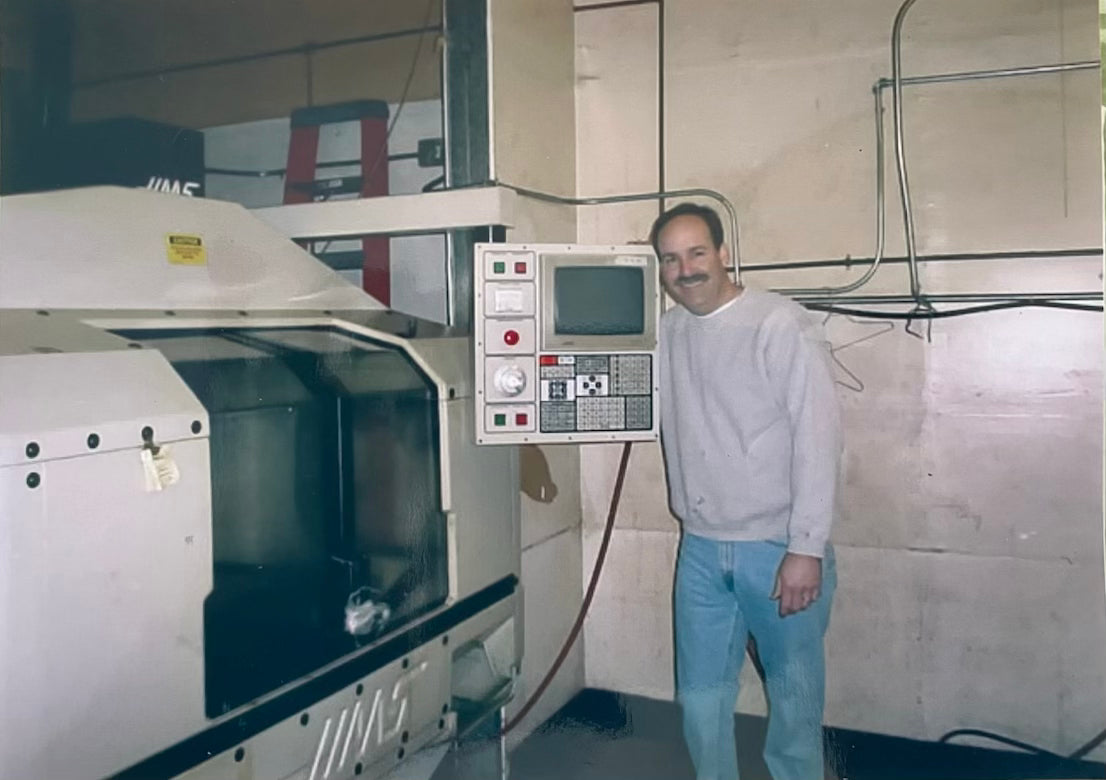

CNC Milled

Crafted with expertise, Kevin Burns putters are precision-milled from a single block of 303 billet steel, eschewing the use of forging or casting methods. Employing the latest milling techniques, including intricate 3-D lines, we create exquisitely crafted putters that consistently lead the golf industry in terms of both fit and finish.